DCDB & ACDB boxes are very important components of a solar PV rooftop project. The main purpose of these boxes is to provide safety to the system and protect other important components of the system such as PV modules, cables, inverters, etc. from faults.

DCDB (DC Distribution Box), also referred to as AJB (Array Junction Box) or CB (Combiner Box), is installed between solar PV modules and the DC side of the inverter. Protection devices such as DC Fuse (Over Current Protection Devices), DC Isolators, DC MCBs, DC SPDs are housed in DCDB boxes.

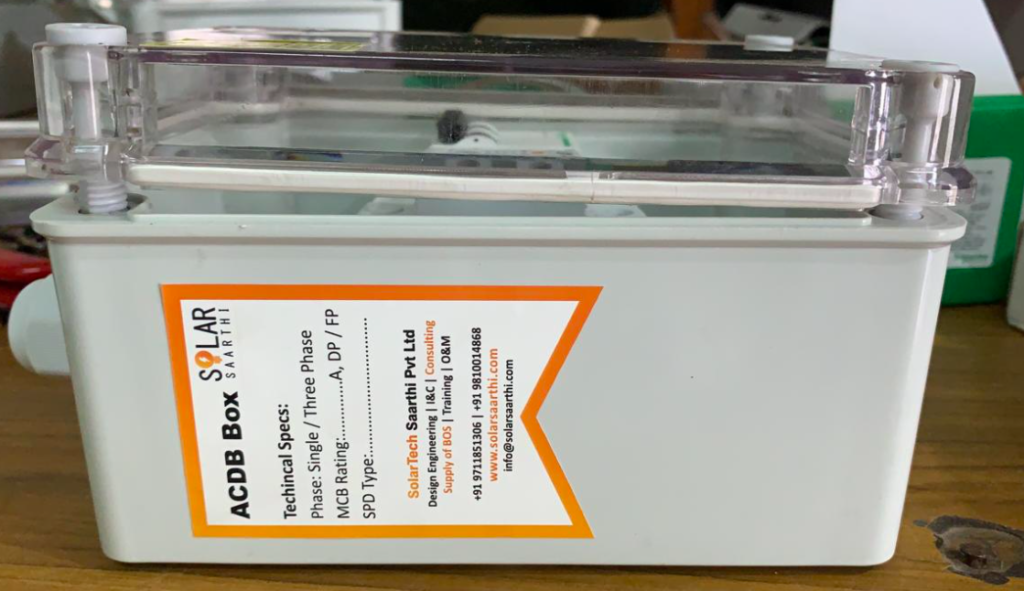

ACDB (AC Distribution Box), also referred to as ACCB (AC Combiner Box) or Solar LT Panel, is installed at the output side of the Inverter and before the main LT panel of the client. Protection devices such as AC MCBs and AC SPDs are housed in ACDB boxes.

Pic credits team Solar Saarthi

Pic credits team Solar Saarthi

Though these boxes are required to increase the protection and safety of the system. But if the sizing and selection of these boxes are not done properly, then these boxes may become dangerous to the project itself.

With the growing competition, reducing margins, and cost-cutting in the industry, many times compromise in the quality of designing and selection of DCDB & ACDB boxes are made.

In this article, we will discuss what one shall consider before selecting DCDB & ACDB boxes for their solar PV rooftop projects.

Material of the enclosures used for DCDB and ACDB boxes

Two types of non-metallic enclosures are available in the market namely: ABS (Acrylonitrile Butadiene Styrene) and PC (Polycarbonate). Visually there is no difference between both the materials but they do have different properties and uses.

PC (Polycarbonate) is a heavy-duty thermoplastic material with excellent resistance to both hot and cold temperature swings. Polycarbonate material is UV resistant and is a highly shock-resistant plastic. These properties make Polycarbonate enclosures best suit for electrical and outdoor applications.

ABS (Acrylonitrile Butadiene Styrene) is a rugged thermoplastic material with a low resistance to temperature swings. ABS material is not UV resistant and is best suitable for indoor applications. ABS is cheaper in price when compared to Polycarbonate.

To reduce the cost of DCDB & ACDB boxes, many manufacturers and suppliers are nowadays using ABS + Polycarbonate enclosures (Transparent cover of Polycarbonate Material and Base of Box as Polycarbonate Material).

Since DCDB & ACDB boxes are to be installed mostly outdoors and are under direct impact of UV radiations and extreme temperatures. It is always recommended by the enclosure manufacturers to use Full Polycarbonate enclosures (Transparent cover and Base of Box both as Polycarbonate Material).

Pic credits team Solar Saarthi.

Also, ABS material can catch fire very easily and act as fuel to the fire itself. On the other hand, Polycarbonate material does not catch fire so easily. We performed a very simple test by burning both the materials. It can be seen in the below video, how ABS material catches fire so easily while polycarbonate material finds it difficult to burn.

Hence, before selecting DCDB and ACDB boxes for your rooftop solar PV projects, don’t fall for lower pricing only. Always check what is the material of the enclosure you are adding to your project. For a safe system, it is always recommended to use Full Polycarbonate material enclosures for solar PV rooftop projects.

0 Comments